EAM Starting Grant 2023/2024

SPACE – Superior Performance through Accelerated Composition Exploration

Power generation and propulsion demand cutting-edge alloys operating in extreme conditions. Superalloys, key to efficient gas turbines and aerospace engines, not only require an excellent high-temperature creep strength, but also exceptional resistance to oxidation and corrosion. However, their significance expands beyond current technologies, as novel high-performance alloy systems are also key in clean concepts like hydrogen-fueled aircraft engines and high-temperature solid-state oxide fuel cells. Additionally, in concentrated solar power plants and nuclear fission reactors, steam turbines are the key component to convert the generated heat into usable electricity. Even in future nuclear fusion reactors, steam turbines are envisaged to extract the massive thermal energy of the plasma and its efficiency increases with the operating temperature, which in turn is limited by the materials’ high temperature strength in presence of steam.

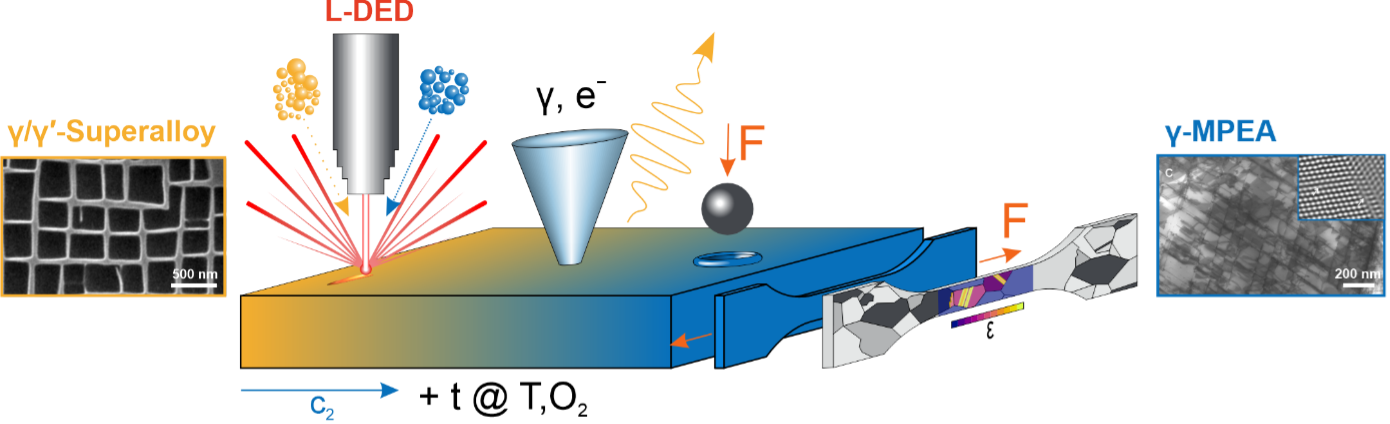

SPACE – “Superior Performance through Accelerated Composition Exploration” aims to revolutionize alloy discovery, development, and characterization. Unlike traditional, time-consuming methods, SPACE employs a combinatorial approach, producing and testing compositionally graded bulk specimens. Through Laser-Based Directed Energy Deposition (L-DED) in inert Ar-atmosphere and high-throughput characterization, SPACE will assess phase stability, microstructure, diffusion, corrosion resistance, and mechanical properties on the meso-scale as a function of composition, atmosphere, temperature, and time.

SPACE will explore three increasingly complex alloy systems: face-centered cubic (fcc, γ) multi-principal element alloys, γ/γ′ Ni/Co-based superalloys, and bcc-derived (body-centered cubic) cubic α/α′/α″ Fe-based superalloys. These systems exhibit considerable compositional overlap, making inter-alloy space exploration an exciting endeavor. The innovative approach allows for rapid alloy tailoring to specific applications and uncovers unique properties in unexplored composition spaces.